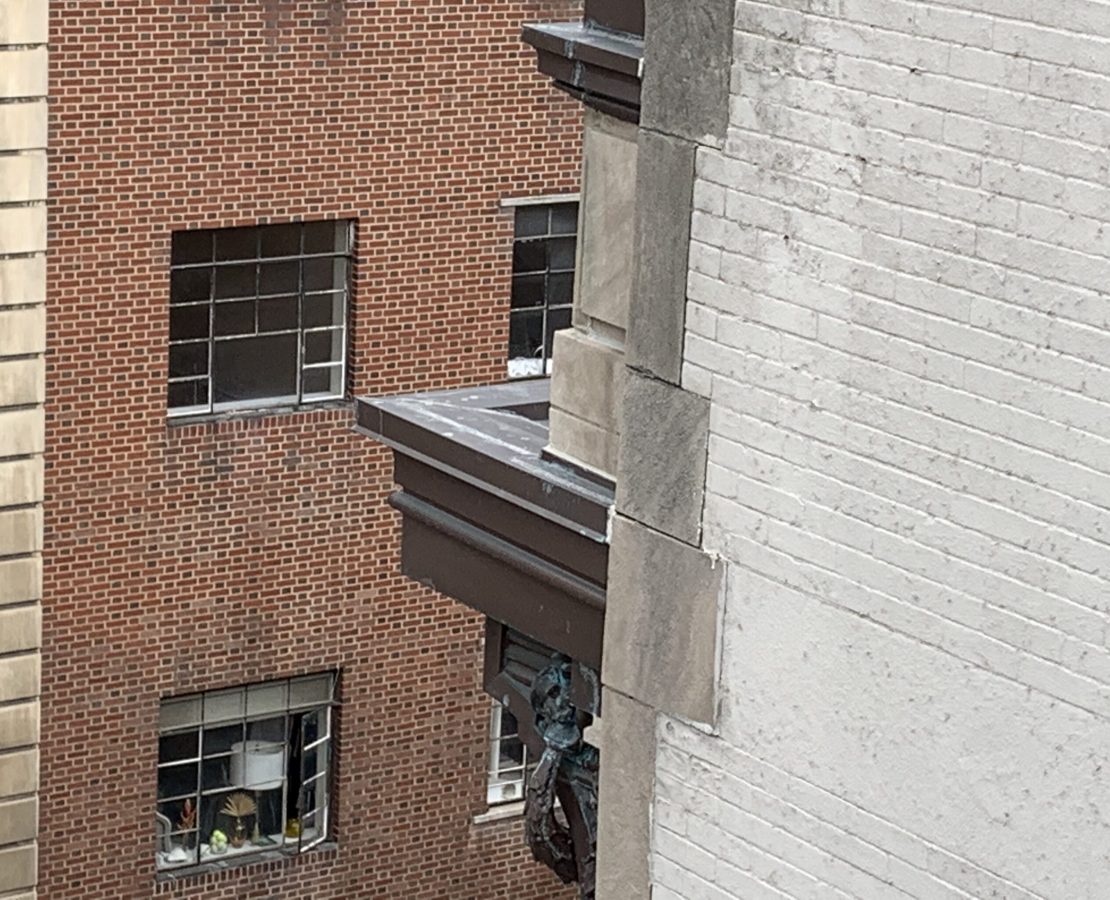

Detailing and joining individual material components into a unified whole is essential to the technical art of building enclosure design. Even basic enclosure details consist of multiple components, each with distinct material properties and performance characteristics that demand thoughtful consideration. To construct a long-lasting assembly, the designer must consider each of the parts, their connections to one another, and how they behave as a unified whole.

Within building assemblies, connections and transitions between dissimilar materials may be concealed, but their impact on the longevity of the enclosure is significant. When those elements join, it is often the connection of these disparate components that determines whether an enclosure performs as expected or succumbs to premature failure.

The fundamental factor critical to a durable and lasting connection between dissimilar components is material compatibility. Materials that behave similarly are naturally most compatible, which reduces the need for specialized or complex details. To join various materials in an enclosure assembly, design professionals must account for the complex ways these different elements interact.

Using detail drawings, knowledge of material properties, and experience with known material interactions, enclosure specialists anticipate and design for the three-dimensional changes and chemical reactivity at each detail or system transition. The building exterior specialist’s job is to streamline these transitions, accounting for material properties and limitations, manufacturer warranty requirements, construction feasibility, and other key considerations. In short, it is the enclosure consultant’s job to see that no detail is overlooked.